Choosing a CNC machining for custom prototypes is essential when you are producing unique products for your business. As the main asset that has a principal part in the production of parts, choosing a CNC prototyping machine that functions properly is essential. However, with so many varieties in the market, getting confused is common. Below are specific things to keep in mind when choosing a CNC prototyping machine.

- CNC Prototyping Machine Materials

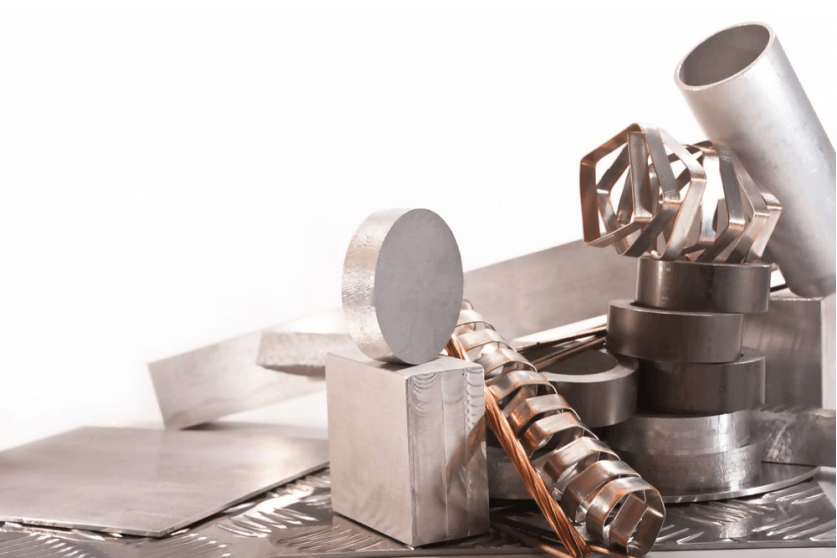

Ideally, the CNC machine is created to work with a variety of products, including aluminum, hardened steel, copper, Inconel, and titanium. However, as since the parts types to be processed affects the design, durability, performance, and precision, it’s essential to consider the specific material you will use. To get the best results, ensure that the machine you choose optimizes the material you use, giving special attention to the motor horsepower, spindle type, spindle speed, and spindle motor torque needed.

- Type CNC Prototyping Machine

CNC machines come in two main types, which include the box guideway or the linear motion. In the creation of custom CNC parts, load carrying capacity, rigidity, speed, and tool life are factors that affect the kind of machine you choose. The linear motion caters for lighter duty applications and hence tends to be faster. The box guide types are ideal for more rigid parts, therefore suitable for larger pieces. To determine what you should choose, consider the kind of material, vibrations created, cutting feed rates, and expected tool life of the machine.

- Current Machine Available in addition to the CNC Prototyping Machine

To fully optimize a CNC prototyping machine that you will use, consider your existing machinery. Consider the current machine manufacturing prices and evaluate the need of the CNC machine and the specific need it’s going to cater to. Understandably, this will force you to analyze its fundamental process hence enabling you to choose a machine that will increase the overalls production effectiveness.

- Complexity Of Parts Created By The CNC Prototyping Machine

Before committing and considering the specific CNC service machine to invest in, it’s essential to evaluate the parts you want to produce. Ideally, different CNC machinery is customizable to different products for precise production. However, to purchase the correct machine, consider the complexity of the creation of the various parts. Doing so allows you to ensure that the production time, effectiveness, and productivity is at its optimum.

- Types Of CNC Prototyping Machine Control System

When considering whether to purchase the various CNC on-demand machinery, its vital to keep in mind the ease of use. Most CNC prototyping machines use automation for comfort, helping with the production process. Unfortunately, some control systems are complex and need a steep learning curve to operate it. When choosing, ensure that the control operating system is easy to use, have reliable controls, and have a stable software system.

Conclusion

Take time and consider the specific products you deal with and let the particular functions act as a guide. To cover your basis, ensure you select one that gives you a multitude of uses in the creation of products. Overall, don’t rush and ensure that the CNC prototyping machine that you choose is suitable for the products you want to deal with.