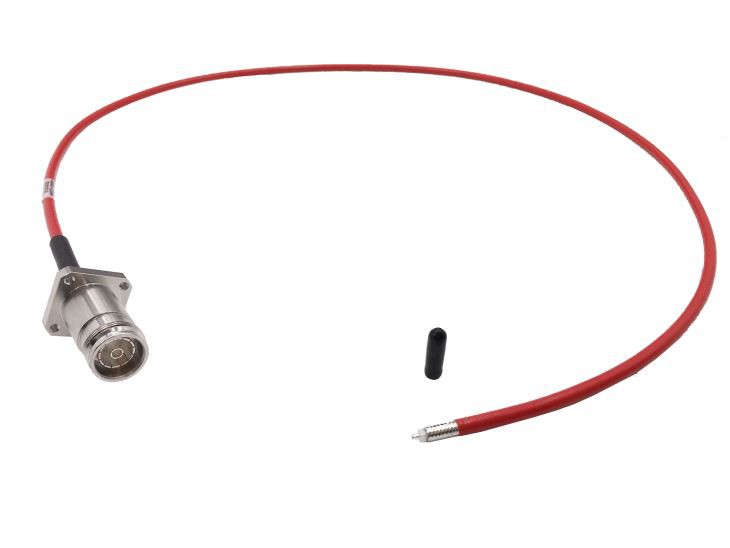

Numerous applications, such as data centers, industrial automation, and wireless communication systems, depend on the 4.3 10 female Square Flange Connector. This connector must be installed and maintained properly to guarantee dependable and durable performance.

Installation

- The first step in installing a 4.3-10 Female Square Flange Connector is preparing the mating surface. The mating surface must be spotless, dry, and free of impurities like dust, oil, or dirt. Any debris on the mating surface may obstruct the electrical connection between the connector and the connected device, resulting in malfunction or poor performance.

- Next, ensure the connector is positioned correctly with respect to the connected device. The connector should be held in place with the mating component to ensure a tight fit.

- It’s crucial to ensure the connector is torqued to the appropriate level. Under-tightening can lead to poor electrical contact and signal loss while overtightening can harm the connector and the device it connects to. The connector’s datasheet or user manual will contain the correct torque specification.

It is advised to conduct a visual inspection after the connector is installed to ensure it is firmly fastened and correctly positioned. Connectors that are too loose or out of place should be tightened or realigned as necessary.

Maintenance

The 4.3-10 Female Square Flange Connector’s long-term performance and dependability are ensured by regular maintenance. Here are some guidelines for keeping this connector in good condition:

Continual Cleaning

Clean the connector frequently to remove any dirt, dust, or debris that may have gathered on the surface. Use a soft, lint-free cloth or a cleaner made especially for connectors. Avoid using harsh chemicals or abrasive materials that could scratch the connector’s surface.

Inspection

Check the connector frequently for any indications of damage, including cracks, chips, or deformities. To avoid potential performance problems or failures, replace the connector immediately if any damage is discovered.

Tightening

Ensure the connector is still securely fastened and positioned by periodically checking its tightness. Retighten the connector to the required torque spec if it is loose.

Environmental Considerations

Consider the surroundings to which the connector is subjected, including temperature, humidity, and contact with chemicals or other substances. Select connectors with the proper environmental ratings to guarantee dependable performance under particular circumstances.

Troubleshooting

After proper installation and maintenance, the 4.3-10 Female Square Flange Connector may experience problems. Following are some typical problems and solutions:

Poor Signal Quality

Poor environmental conditions, loose or damaged connectors, interference from other devices, and poor environmental conditions are just a few causes of poor signal quality. Ensure the device is properly grounded and isolated from any sources of interference. Check the connectors for any damage or slackness.

Intermittent Connection

Several things, including incorrect alignment, loose connectors, or a damaged cable, may bring on problems with intermittent connections. Examine the cable for damage or wear, and check the connectors for proper alignment and tightness.

Signal Loss

Several things, including unfavorable environmental conditions, harmed connectors, and improper cable routing, can result in signal loss. Ensure the cable is properly routed and grounded, and check the connectors for any damage or slackness.

Conclusion

Proper installation and maintenance are essential to ensure the 4.3-10 Female Square Flange Connector’s dependable and long-lasting performance. It is used in a variety of applications. You can help ensure your connectors function optimally by following the best practices described in this article, such as correctly preparing the mating surface, ensuring proper alignment and torque, and carrying out routine maintenance and inspection. Additionally, you can help avoid potential failures and guarantee the ongoing dependability of your system by promptly and effectively resolve any issues that crop up.