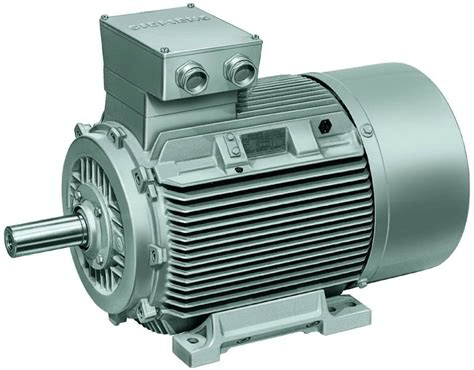

A motor unit of any kind can generate motion. It converts electrical energy into mechanical energy. Motors are widely used, and you might be surprised at how common they are. They are almost everywhere in our surroundings from our computers, kitchen appliances, toys, switches, hairdryers, microwaves, etc. Motors can be classified among the most significant inventions. Different current (DC) or alternating current (AC) are used to run the motor, and both have advantages and disadvantages. There are many types of motors, and also customization is available. You can check out more on motors on a Stepper motor gearbox. Other than stepper motors, in this write-up, we will look at the types of motors in this extract.

Types of motors

AC motor

It is a motor that uses alternating current to operate. There are two types of AC motors, i.e.,

a. Synchronous motor

It does not rely on slip induction for it to run. It uses permanent magnets on an independently excited rotor winding. The torque it produces is usually synchronized in speed. It is ideal for driving equipment at a constant rate.

b. Asynchronous motor or an induction motor

A stator winding uses electromagnetic induction after which electric currents are produced in the rotor; thus, torque is produced. There are two types of induction motors.

- Single-phase induction motor-Used for small loads like home appliances.

- Three-phase induction motors-This are mainly used in industries or big manufacturing plants.

DC motor

It is an electric motor that converts current from electrical energy to mechanical energy. They have an internal mechanism that changes the direction of current flow in the motor. There are two common types of DC motors.

a. Brushed

They are used when one is looking to save on cost and where the system application is simple and basic. Usually, the brushed motors are 75%-80% effective and are divided into four.

- Series wound

The field winding is connected in a series with the rotor winding. The speed varies, and it develops a large amount of starting torque. Speed control is usually poor because as the torque increases, the speed falls. These types are commonly used in automotive, lifts, etc

- Shunt

The field winding is joined in a parallel way to the rotor winding. The speed regulation is proper as torque increases without reducing the speed by increasing the motor current. They are ideal for use in equipment like vacuum cleaners.

- Compound wound

It is a combination of the series and shunt motors. Series has better starting torque while shunt is suitable for regulating speed.

- Permanent magnet.

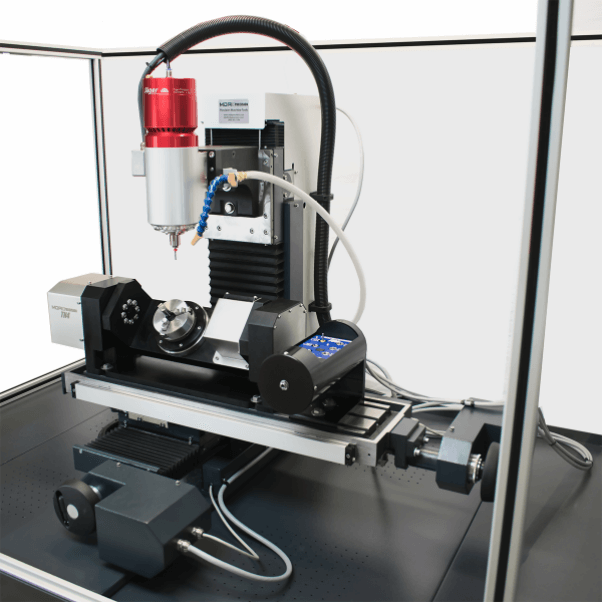

It uses a magnet hence the name. The ability to start torque is excellent, and the regulation of speed is quite good. It requires low torque and precise control to run. They apply to robotics.

b. Brushless

They don’t contain brushes as the name suggests; hence they are mechanically simpler and use the DC. The motor usually has permanent magnets, four or more around the rotor. The rotor and stator turn at the same frequency. Brushless motors are 85%-90% efficient.

Conclusion

There is a variety of motors in the market, making it efficient for anyone wanting to buy one. Make sure you know your system application, for you to choose the most suitable motor.