Prototyping is a process that involves experimenting with designs and implementing ideas. Depending on the manufacturer, prototypes are built in different Fidelity degrees, mainly to capture concepts of designs and test them on users. You can contact DDPROTOTYPE if you want to create a prototype of any product.

With prototypes, designs are refined and validated, do a brand can be able to release products that would satisfy the consumers.

Types of Prototyping

1. Rapid Prototypes

Whenever you have a deadline you need to catch up to, rapid Prototyping is the type of Prototyping your entire team should use. It could help meet the working demonstration of your product. This is created with reduced costs too. Rapid Prototyping helps in the mitigation of costs and creates designs that work in short time frames.

Prototypes involve a rapid process that lets designers explore some concepts faster, which brings them to life. These techniques help manufacture companies. These create prototypes that work that could become expensive in the future.

2. Wireframes

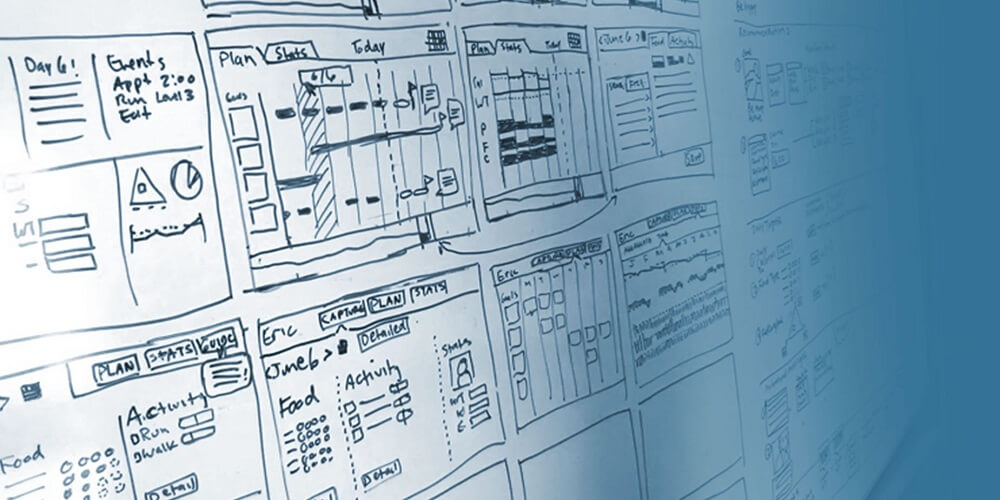

These wireframes lead to prototypes. They are also a type of prototype. Terrific wireframes act as blueprints for design projects. These have elements of end designs and conceptual ideas.

The best software for wireframe is complete with prototyping, wireframe, and conceptual tools. These take designs from blueprints and use them on prototypes which work all on the software programs. Wireframes specifically create opportunities for team members and clients to create feedback on one’s design. This allows for more effective final products and prototypes.

If you have not made use of a wireframe to create your designs, you do not need to make use of an overly complex high-end tool or wireframe. To create an effective wireframe, use a blueprint that could be edited and created with just paper and pen.

3. Mock-ups

Mockups refer to a visual representation of what the final products will look like. This gives users and clients the whole idea of how your design would look after it is completed. Simply put, mockups do not have other features neither do they serve any function. They only show users or investors a preview of the project.

Advantages of Mockup Prototyping

If you are searching for a fast way to show your investors’ design or give your team members something to handle quickly, mockups are efficient ways to do this. They could be used in the promotion of your product before its time for their launch. You could gather all the things your potential users say and know how you could re-organize your project to meet their preferences.

In all you do, note that It would be best if you were sure to fix all mistakes from your prototypes as you use any type of prototyping. This is are necessary before you release your final product, as you can use these prototypes to know design problems. This also helps you to create your products easily next time.

Final Thoughts

You can handle your conceptual designs using the varieties of prototyping. With this, you can take your designs to better levels. It also allows you to get a model which functions and also for users to test your product.