Injection molding requires that the plastic wall thickness be stable enough in order to maintain the overall structure and quality. If you are not so sure about the recommended wall thickness, keep reading because we have put together a couple of tips to guide you and prevent you from making some big mistakes that compromise the integrity of the final product.

Apart from the thickness, what other factors should you consider?

Besides the thickness of the product walls, there are other factors that you also need to keep in mind so that you’re in a better position to determine how thick or thin the wall should be. These factors are:

- Will the wall be used for structure?

- If a certain part is made thin, will it be fragile?

- Does the material you use affect thickness?

Generally speaking, there are three main variables that you must consider which are very important when it comes to determining the thickness: the material composition, the flow rate, and the part yield.

- Material Composition. The composition of the material determines its stiffness and strength characteristics. The stiffness refers to how the material bends when a force is applied and strength refers to the material’s ability to withstand fracturing.

- Flow Rate. This refers to the rate at which the molten material will flow into a mold. Problems with the flow rate can cause mistakes like voids and sink marks.

- Part Yield. This refers to the ratio of good parts to bad parts. Thin walls count as low part yield and need to be discarded. This results in unnecessary losses for the manufacturer which also leads to delays.

What most manufacturers do is set a consistent wall thickness regardless of what material they’re using. However, others make necessary adjustments depending on what material is being used.

Is There a Recommended Wall Thickness For Injection Molded Parts?

It’s very important that you work with manufacturers to help you select materials and their appropriate thickness. Working with professionals ensures that the parts that you end up with are cost-effective and are produced in a timely manner. Generally, the thickness of the parts depends on the material being used.

Injection molding is a very reliable process that has gained popularity over the years. Its biggest advantage is that adjustments can be made so that the end product fits your specific needs. On average, the minimum wall thickness of the parts ranges from 2mm to 4mm/

Mistakes to avoid during injection molding

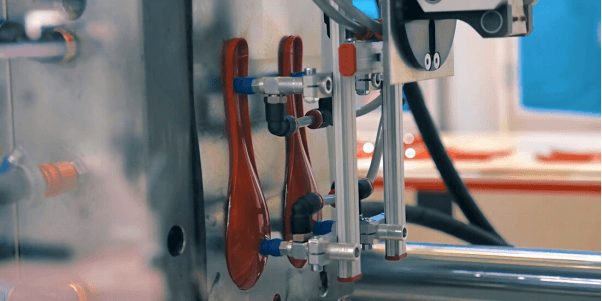

This manufacturing process involved the creation of molds that are made using either hardened steel or aluminum. The mold takes the form of a pre-determined shape, usually after the molten material is fed into a cavity where it then cools and hardens.

It’s every manufacturer to create high precision parts. However, it’s not uncommon for them to face some challenges during production. Here are 3 common mistakes that manufacturers should avoid:

- Making non-uniform walls

The thinner’s parts of non-uniform walls cool off quickly while the thicker sections cool off much slower. As the thick parts cool down, cracks may occur.

If the need for non-uniform sections is unavoidable, the molding of the different sections should be done gradually.

- Not utilizing draft

These drafts make it easy for the parts to be removed from the mold. They must be in an offset angle parallel to the mold opening and closing.

- Making sharp corners

Sharp corners are known to cause part failure after the stress concentration to get high. To minimize the stress concentration, increase the radius.