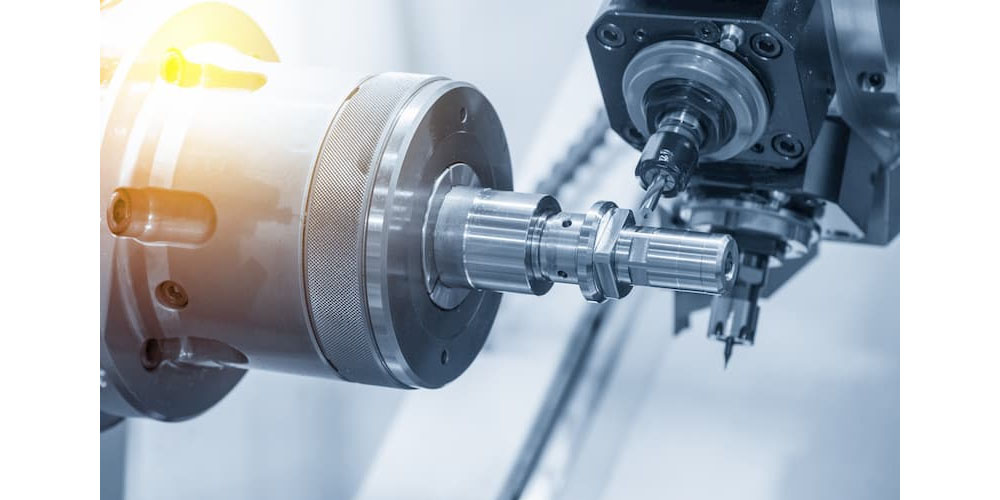

The manufacturing industry has made a revolution turn to embrace production technology, which has made a significant impact on the quality of the products. CNC machining is one of the most in-demand modern manufacturing processes. Companies offering the best CNC machining services to innovative companies use the latest CNC technologies to produce high-quality precision parts. This article discusses the latest technologies in the CNC industry.

Latest Technologies in CNC Machining Production

The recent advancements in CNC technologies are taking manufacturing to another level; innovative companies are faced with new challenges and demands every day. These demands have prompted companies to use automation or a human machine to sustain the increasing market needs. These are the advanced tech features of CNC equipment and human operators;

1. Multi-axis Machinery

The oldest CNC machine has two axes, X and Y, which means the table moves left and right. If the machine had a third axis, the axis allows the quill to move up and down. The more axis the equipment has, the more it is capable of producing complex parts effectively. An equipment can have up to seven axes; this is a complete set capable of manufacturing intricate pieces in one go.

The Multi-axis CNC equipment manufacturing system concedes the modularity concept, allowing more axis to be added to the machine. If the machine had just three-axis, it could be easily upgraded to four.

2. Smart Machines

Smart machines are linked to a set of technological instructions enabling them to work under their command. This ensures continuous production of the same high-quality parts. They are also used for online testing of interim designs, which are polished and corrected until a final layout is obtained. The configuration can be stored to create a prototype.

The use of smart machines has lessened the need for manpower; that said, you will still need a team of experts to help in the operation and maintenance of the machines. As much as the machines might be expensive, they ensure a smooth manufacturing process and a reduced innovation risk.

3. Manpower Functionality

The ever-changing world of technology requires a more skilled team. You might be obliged to train and retain your current staff or hire a competent team. Technology advancements in CNC machining affect the functionality of your labor force; most of these advanced machines are self-operating. They require minimal human assistance. These machines assure total accuracy, and if a problem occurs, an alert will be sent warning about the same.

Conclusion

The scarcity of skilled programmers and proficient machinists is why manufacturing companies embrace technology and move to automation. With these technological advancements, machines can create unique designs without errors. The programs should be error-free because the machines follow the program instructions to the latter. This means that any mistake can lead to the production of an undesired product.

Advanced CNC machinery can have robotic attachments that make them more efficient compared to traditional machines. The accuracy of the production makes CNC machining technology a lucrative and optimal manufacturing process. The technology also contributes to increased production.