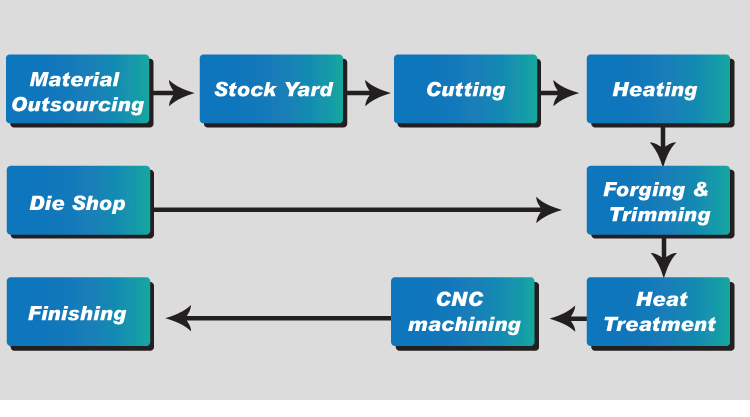

Manufacturing Process is one of the main parts of the production process. It is that process which involves the changes of sizes/dimensions or shape of the part. Transportation or material storage is not a part of the manufacturing process. This article is dedicated to explaining different types of manufacturing processes.

Manufacturing Process Classification

Different materials are needed for manufacturing. So before starting the manufacturing process the properties of the engineering materials should be known. Available engineering raw materials needed for manufacturing, equipment, tools, and machines all are of great significance.

These materials, equipment, tools, machines are mainly made of metals which are collected from ores. The metals are extracted from the ores and then molten metal goes through some foundry processes. Pre-foundry processes involve the purification of the metal. These pure molten metals are poured into the moulds and thus we got ingots. These ingots are processed in some other mills to get the desired shape. Thus we get billets, blooms, slabs, sheets and rods or tubes. These shapes further go through some other processes and usable shapes are obtained. Usable shapes are done in different machining and manufacturing shops. We will discuss the six major groups used to convert ingots into usable metals. So let’s start-

First One – Primary Shaping Process

Primary shaping process is used to give the amorphous material a well-defined shape. Some of the primary shaping processes produce final products and other needs additional machining works. Primary shaping process involves casting process, plastic forming technology, powder metallurgy, bending of the metals, forging and gas cutting and many more. For example, in casting technology, the molten metal is needed to be poured on the moulds and it needs to cool down. Afterwards, the cooled metal object may need some extra machining through grinding or lathe machine or some milling operation. Please Read: Different Casting Process Explained.

Second- Machining process

As mentioned earlier primary process may not give the complete finished goods. Machining is one of the processes of making the primary shapes into finished goods. The components or parts are subjected to machine shops for finishing. It is used to give desired shape and size to the cylindrical and flat objects. The process to remove unwanted materials from the jobs using cutting tools is known as machining. The purpose is to give perfect dimension and desired shape. Machines used for these operations include lathe, milling, drilling, shaper, planner etc. The materials subjected to machining operations include the shapes of a bar, rod, tubes and flat surfaces. For greater dimensional accuracy and surface finish the machining processes are important. They also provide the good surface finish. At the time of machining different multi-point cutting tools, jigs and fixtures and measuring devices are used. Machining produces a lot of waste metals in the form of chips. These days CNC machining is used for better accuracy and quick machining. Turning, knurling, parting, facing, boring, reaming, slotting, punching, threading, milling, gear cutting are some of the metal removing processes. For a better idea about machining tools follow The classification of machining tools.

Third – Metal Forming process

Metal forming is another manufacturing technique used to give the metal desired shape through the application of pressure/stress, forces like compression or tension or shear or the combination of both. By applying these forces permanent deformation of the metal is achieved. These processes are also known as mechanical working processes. These mechanical working processes are classified into two categories, one – hot working processes and two-cold working processes. Metal forming process does not incorporate metal removing. The metal is deformed and sometimes displaced by the application of forces. Metal forming always include plastic deformation. In this technique, directly usable articles can be made. Wires, rods, cold drinks bottles, tubes are made by the metal forming process. The hot working process includes forging, hot spinning, rolling, extrusion, hot drawing etc. Cold Working Process include cold forging, cold rolling, sheet metal working, punching, piercing, squeezing, notching etc.

Fourth –Joining Processes

Joining is a process we are using in our everyday life frequently. Different sub-assemblies are joined together to get a completely assembled product. In fabrication process joining is used frequently. In manufacturing or fabrication, two or more metal parts are put together and joined by means of fusion, riveting, screwing, applying pressure and rubbing. These joining processes are needed to make air-tight joints and semi-permanent and permanent fasteners. These joining techniques are very important in making bigger assemblies. For example, an aeroplane is assembled by putting together more than a thousand subassemblies. The joining process includes different types of welding, soldering and brazing, riveting and screwing, pressing, nut and bolt joints etc. Please Read:

Fifth- Surface Finishing

Surface finishing is a process which is applied to get the desired levelling of the surface and also to obtain the desired smoothness. Very negligible amount of the materials is removed from the surface by this process and does not involve any effective change in the dimensions. It is not an effective metal removing process and should not be confused with the machining process. Putting some kind of coating over the metal is also a surface finishing process. Various surface finishing processes include honing, lapping, super finishing, sanding, deburring, electroplating, buffing, painting, anodizing, galvanizing etc. Sherardizing, Parkerizing, plastic coating or metal spraying is also known as one kind of surface-finishing process. Surface finishing provides excellent finishing of the metal surface and at the same time gives good protection from the environmental contaminants.

Sixth- Processes that involve the changes in the material properties

Different properties of the same metal are desired for different applications. So metal property is needed to be changed in those cases. Material property change may include improved hardness, greater ductility, durability etc. For some particular uses or operations, suitable properties are needed to be incorporated. Some operations need softer material, some need harder. The properties of the materials change when the total grain size of the materials are regrouped or reorganized. Different grain conditions provide different properties. The grain sizes are changed by the application of different heat treatments. By heat treatments, the internal structure of the material is changed. And they achieve different improved properties. Common heat treatment methods include –annealing, hardening, case hardening, normalizing, grain refining, tempering and age hardening etc.